Automate the PO Cycle with Procurement Software

As a business grows, its procurement cycle becomes increasingly complex. The process consumes more resources, time, and talent.

Transferring that workflow to a procurement software solution takes advantage of the benefits that automation offers: trimming time, expenses, and stress from the procurement process.

Automation through procurement software reduces human error and increases efficiency as fewer assets are required to complete a task.

Staff can dedicate their time and talents to more valuable tasks as repetitive and manual data entry tasks are no longer required.

Software also connects all users within a controlled hierarchy of access, review, approval, and payment.

When a PO is submitted, it automatically routes it to the right people for approval. This significantly reduces PO cycle time and errors.

Instead of chasing down approvals, teams are able to use their work hours more effectively.

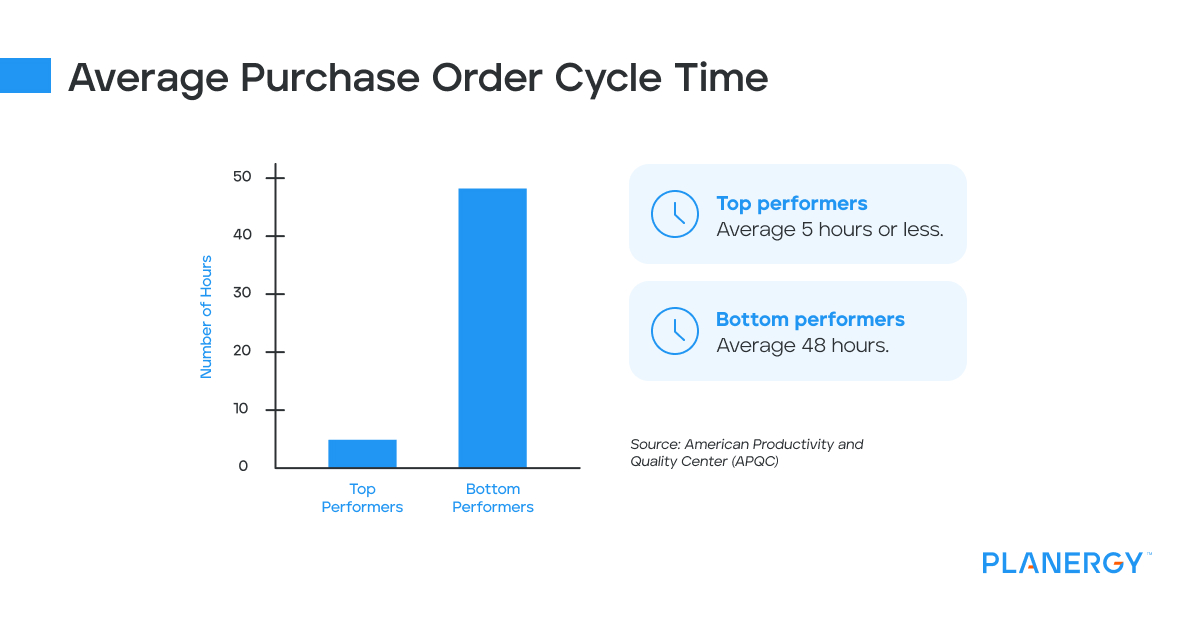

According to the APQC, companies using automated software complete their PO cycle 11 hours faster than those using manual processes.

Those 11 hours saved per PO using purchase order automation can be used to generate value through higher value tasks such as supplier relationship management (which can further reduce PO cycle time, see below).

Procurement software also connects all transactional data with related documentation. Every PO is automatically tied to its corresponding invoice, shipping documents, correspondence, and vendor information (including contract terms, incentives, and penalties).

This makes errors rare and easy to correct if they occur, and greatly simplifies the auditing process.

Review Your PO Policy To Reduce Unneeded Steps

Over time, procurement teams can add unnecessary steps to their approval workflows.

These may have made sense in the past, but perhaps they are no longer relevant, especially if you’ve switched from manual workflows to automated processes.

Reviewing your purchase order policy regularly and updating where required will ensure operational efficiencies are not lost to bureaucracy.

You may be able to set certain spending thresholds where individuals can approve their own orders up to a certain total amount for the month or year.

More detailed approvals can be reserved for higher-value orders, or specific scenarios where oversight is necessary.

Getting rid of unnecessary approvals can make a big impact on reducing PO cycle times.